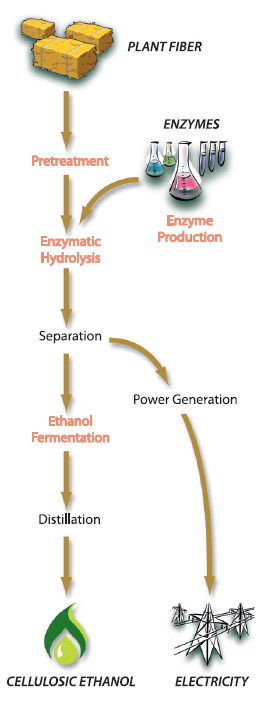

Iogenís cellulosic biofuels technology incorporates all of the necessary steps required to convert a wide variety of cellulosic feedstocks into ethanol and other biofuels. A brief description of the Iogen process follows:

Feedstock handling: When feedstock is specifically sourced and trucked to a facility, it is received and tested at the main plant gate scale house. Feedstock trucks are then routed to onsite storage or directly to the unloading area serving the plant process. Once in the process, the feedstock is processed to reduce the particle size. When the facility is co-located with a sugarcane mill, bagasse is drawn either directly from the process or from a storage pile. No further size reduction is required. In both cases, the feedstock is processed to remove debris, sand and other impurities.

Pretreatment: The pretreatment process is a high temperature, short residence time, mild acid hydrolysis which breaks down the feedstock and prepares it for enzymatic hydrolysis. It also breaks down the hemicellulose component of the feedstock into five-carbon sugars. Pretreatment requires water, chemicals, and high pressure steam, and energy is recovered for re-use elsewhere in the process.

Enzymatic hydrolysis: The enzymatic hydrolysis step is a multi-day operation run under mild conditions. It receives feed slurry from pretreatment, and with the use of enzymes breaks down cellulose to produce six-carbon sugars.

Lignin separation and processing: In lignin separation, the product of hydrolysis is split into solid and liquid portions. The solid portion consists mainly of lignin, which possesses a high heating value, thus making it an ideal fuel for burning in a boiler. The combustion of lignin provides enough energy to power the process. The liquid portion, which contains the sugars, is then sent to fermentation.

Ethanol fermentation and distillation: The five- and six-carbon sugars are converted to ethanol using genetically modified yeasts. A dilute ethanol stream, known as beer, is generated as well as carbon dioxide. The fermentation beer is concentrated into commercial-grade fuel ethanol. The residue from the first distillation column is further processed through an evaporation step.

Process integration: The process is designed to minimize the use of water and energy through efficient heat integration, water recycling and co-product recovery. For example, in a stand-alone facility, condensates and waste streams from the process are treated in an anaerobic digester and clean water is recycled back as process makeup water.

|